Sushrirekha Das1, BiswaRanjanSamantaray*2, Manorama Das1, Nityasundar Pal1, and Mahidhar Bolem1

Introduction

Biofloc culture is a profitable method of fish farming which has become very popular allover the world and is considered as an alternative to open pond fish farming. Biofloc technology is a technique of enhancing water quality in aquaculture by stabilizing carbon and nitrogen in the system. It is an ingenious and cost effective technology in which toxic materials of the fish such as nitrate, nitrite, ammonia can be converted to useful product, i.e., proteinaceous feed in situ.

The principle of this technique is to recycle nutrients. Bioflocprovides an additional source of feed and helps in cleaning the culture water of the fish. It is the technology used in aquaculture system with limited or zero water exchange under high stocking density, strong aeration and biota formed by biofloc. The culture of biofloc will be productive or fruitful in the case of culture tanks exposed to sun. Rearing of fish at high density requires some waste management system. Biofloc is a waste treatment system at its core. It was developed to prevent diseases from incoming water to a farm. It is a sustainable and eco-friendly process.

Working of biofloc system

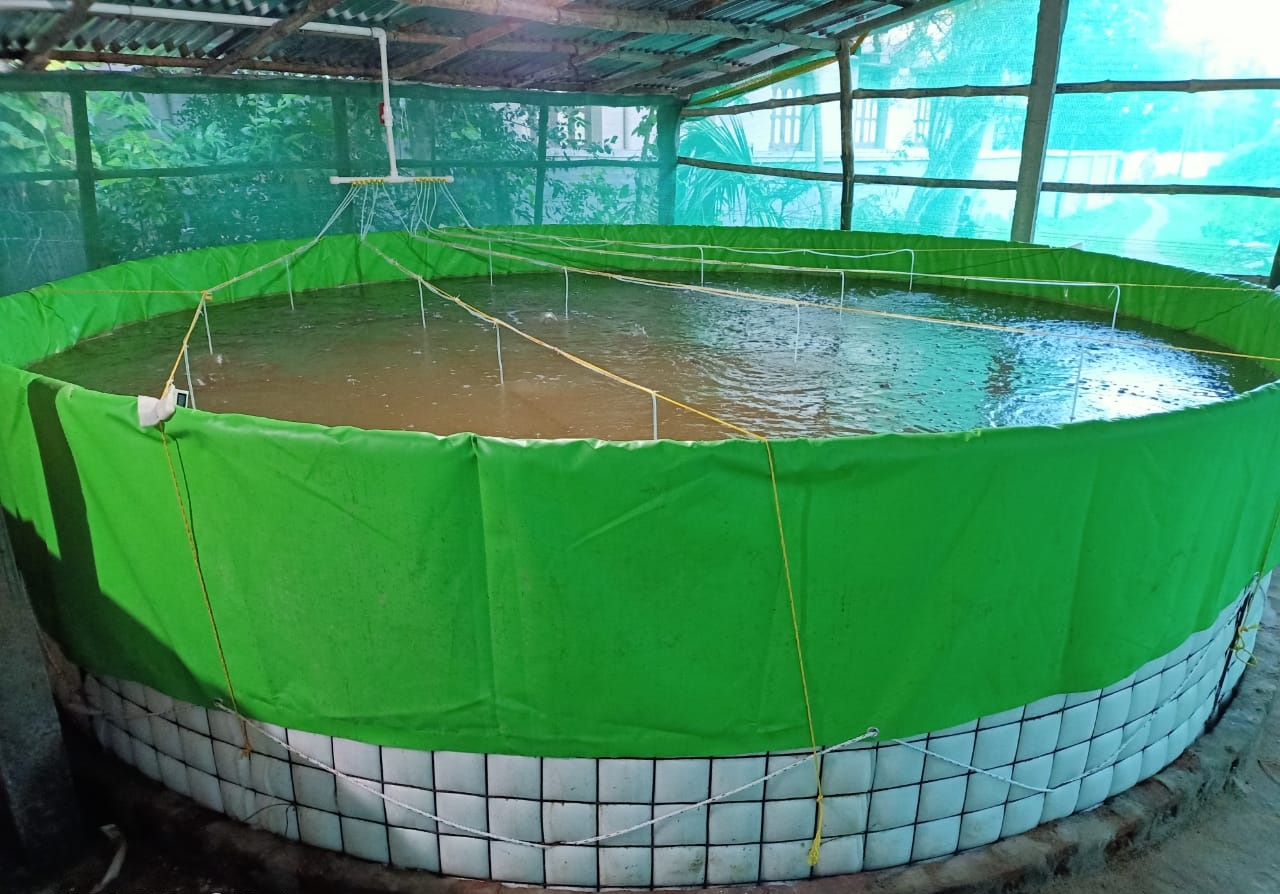

This profitable method of fish farming is practised in a tank, which are of different sizes and the most common size used is of 4 diameter. Biofloc technology is the technique that converts unused feed and aqua animal faeces into food in a culture system while being exposed to sunlight creating a protein rich live feed in situ. By the excessive conversion into food again, the cost of feeding comes down.Heterotrophic bacteria are the major constituent of Biofloc culture which reduces the ammonia and nitrite produced by fish feeding.

These heterotrophic bacteria consumes ammonia by converting it into protein and this can be consumed by fishfor growth. It functions as an actual feed for the fishes and it’s nutritional values are also superior. Studies indicated that biofloc contains high levels of protein 38-50%, lipid 3%, fiber 6%, ash 12% and 19 kj/g energy.

Protein levels in biofloc depend on the crude protein in the diet and carbon sources applied. Poly unsaturated fatty acids in biofloc contain 27-28%, mono-unsaturated fatty acids 28-29%, and 30-35% of saturated fatty acids. The number of bacteria in biofloc pond can be 106 to 109 per ml of floc, which contains 10-30 mg dry matter and bacteria produce 60-600 kg/ha/day of protein for fish. Even though biofloc have sufficient protein to maintain significant fish growth, however, supplementary feed is essential and its quantity has to be adjusted on the basis of biofloc volume.BFT has been applied to culture various fin fishes.

The species having characters of the filter feeding habit, omnivorous habit and digestive system adoptable to assimilate the microbial protein are the candidate species to biofloc technology such as Oreochromisniloticus, Cyprinuscarpio and catfish (Clariasbatrachus) and climbing perch (Anabas testudineus)Anabas. The BFT has suitable for nursery, grow out phases and even to enhance breeding capacity.

Double farmer’s income

This profitable method of fish farming or Bioflocfarming cuts down all the major costs or expenditures so that the savings can be really more. The farmer will not face any problems such as huge operational costs, cost of vast lands, high costs of feeding, disposal and discharge of waste sludge when one opts for this method. The Odisha Government offers a subsidy of 40% for general people while 60% subsidy is given to SC and ST beneficiaries.

In aquaculture, the major expenditure is due to feeding ingredients for fishes. When fishes are fed with high protein diets, approximately 70% of it is discharged as waste in surrounding culture water in the form of nitrogen. One can recycle this waste into feed again by reducing the expense of high protein feedsusingbiofloc technology.

Bioflocculture also reduces the risk of introduction and spread of pathogens thus by improving the fish health.In normal pond based farming system, 1acre of earthen tank (4000 sq. meter area) produces around 2,000 kg of fish in six months and in bioflocfish farming system, the two same 2000 kg fish can be produced only from four small tanks of each 4 meter diameter and 1.2 meter depth installed in a floor area of about 100 to 150 square meter. Each Biofloc tank is stocked with 1000 to 1500 numbers of quality fish fry of 2-3 cm or fingerlings of 8-10 cm with a target of 500 kg fish production in 6 months. Generally, fish grows to about 200 gm in 3 months and 700-800 gm in 6 months.

Hence, depending on the local market demand, fish can be partially harvested regularly and the farmers can also get good price by selling the fishes in live conditionsto generate daily income for the farmers.The technology best suitable for the areas where the land and water availability is the major constrain.The technology is also women friendly as there is no such criticallabour involvement required after the installation of the tank (BFT).Biofloc systems rely on photosynthesis for the conversion of uneaten feeds, faeces and excess nutrients into food. By converting ammonium into microbial proteins that can be consumed by filter feeders, Biofloc systems are able to double this figure and thus helping farmers to save some money.

(The authors are 1Scientist Marsco Aqua Clinics Pvt. Ltd., (AOC), Balsore, Odisha, 2Scientist (Fishery Sc), KVK, Mayurbhanj-1, OUAT, Odisha respectively. Views expressed are personal.)

(Please share your experience, interesting news articles and case studies at aquapostnews@gmail.com)